Providing Performance Critical Solutions for the Airforce

Trelleborg understands your need to protect your assets, Our engineered polymer solutions can be found in the deepest oceans to the furthest reaches of outer space.

Trelleborg specialises in engineered polymer solutions with the ability to seal, damp and protect critical applications within adverse environments.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Trelleborg specialises in engineered polymer solutions with the ability to seal, damp and protect critical applications within adverse environments.

We provide customised solutions using proven materials and technologies to meet client needs and requirements.

Trelleborg has more than 40 ISO certified manufacturing facilities worldwide and can support projects with established defence technologies and application expertise.

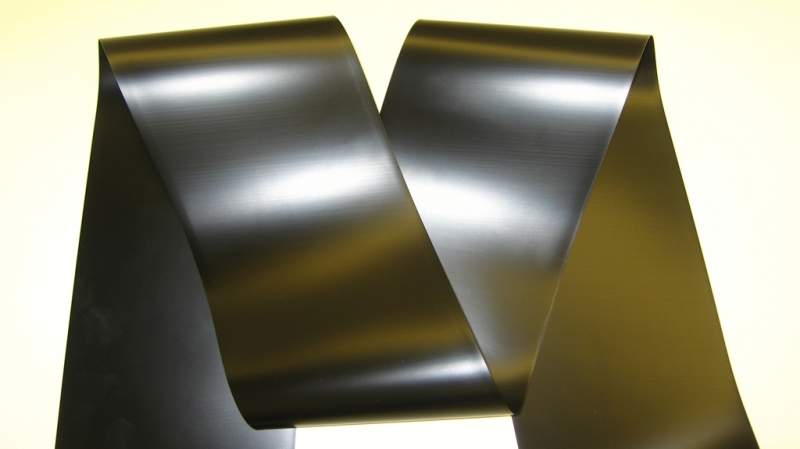

Trelleborg manufactures a wide range of erosion materials that protect components from extreme environmental conditions in terms of surface protection and extended in-service life.

They are specified for both fixed-wing and rotary-wing aircraft applications, and can be used on modern composite constructions and wooden propeller blades.

CONFOR® foams offer a unique combination of properties that are ideal for high-energy absorption applications that enable them to dissipate shock and impact.

The solution is also used for high-energy absorption applications such as comfort management and protective padding applications.

Trelleborg’s Aerokler™ and AeroklerF™ aircraft ground refuelling hoses for kerosene or petroleum fuel are lightweight, flexible and abrasion-resistant hoses.

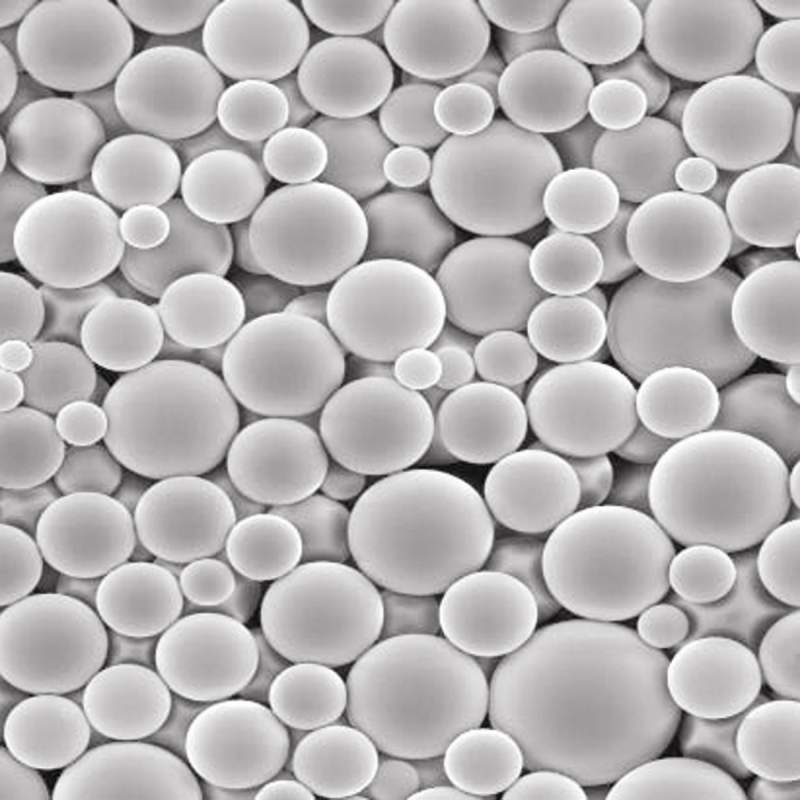

The company supplies a broad range of aerospace-grade, high-purity, lightweight glass and ceramic microspheres with uniform wall thicknesses and consistently sized distributions that can be tailored to client requirements.

New-generation microspheres are being manufactured to improve flame retardation in composite compounds, reduce the detectability of aircraft by radar, protect delicate electronic components, and decrease vibration in jet engines and paint weight.

Protecting people, structures and equipment from all types of fire in this extreme environment is essential to ensuring on-board safety.

Trelleborg’s certified rubber-based passive fire protection technology protects structures from chemicals and corrosion. The dampening, noise-reducing flexible nature of Firestop™ protects equipment from vibrations, collisions and explosions.

Trelleborg’s radar-absorbent material (RAM) can be applied to a platform in a variety of forms, enabling the most suitable material to be used across a wide range of applications.

In addition, radar scattering and absorbing materials can be combined with camouflage, infrared (IR) and thermal materials to provide multi-spectral signature reduction.

As a world leader in engineered polymer solutions, Trelleborg is able to seal, damp and protect critical applications in demanding environments. Our innovative solutions are designed to accelerate our customers’ performance in many different ways – from improving functionality to increasing productivity. Trelleborg is able to provide tailored solutions using proven materials and technologies to meet the defence needs and requirements.

With more than 40 ISO certified manufacturing facilities globally, Trelleborg can support your projects with proven material and application expertise developed for the defence industry.

Our products and solutions are taking performance to new levels, ensuring that we provide a competitive advantage to our customers by ensuring a long-term business partnership. Our products and solutions are for life of the application and are class leading in compliance with material experts and proven track record.

Trelleborg understands your need to protect your assets, Our engineered polymer solutions can be found in the deepest oceans to the furthest reaches of outer space.

As a world leader in engineered polymer solutions, Trelleborg is able to seal, damp and protect critical applications in demanding environments.

AN-132 is a new light, multi-purpose transport aircraft being developed by Antonov and Taqnia Aeronautics Company. The aircraft is based on Antonov An-32 (Nato reporting name: Cline) twin-engine turboprop.

Calidus B-250 is a next-generation light attack / trainer aircraft developed by Calidus in collaboration with Brazilian firm Novaer, Rockwell Collins and Pratt & Whitney Canada.

Trelleborg’s applied technologies operation will exhibit its range of buoyancy materials at Oceans 2018 in Charleston, South Carolina, from 22-25 October.

Trelleborg’s offshore operation launches its next-generation Firestop™ material. The newly developed fire-resistant material is thinner and lighter than any current passive fire-protection materials available to the market.

Trelleborg manufactures a wide range of erosion materials that protect components from extreme environmental conditions in terms of surface protection and extended in-service life.

Trelleborg's Aerokler™ and AeroklerF™ aircraft ground refuelling hoses for kerosene or petroleum fuel are lightweight, flexible and abrasion-resistant hoses.

Trelleborg supplies a broad range of aerospace grade, high purity, lightweight glass and ceramic microspheres with uniform wall thicknesses and consistent-sized distributions that can be tailored to requirements.

Protecting people, structures and equipment from all types of fire in this extreme environment is paramount to ensuring on-board safety.

As the sophistication of acquisition sensors and weapon systems increases, signature management and deception techniques are playing an even more important role in modern warfare by increasing the survivability of vital assets.