The US Air Force Research Laboratory (AFRL), along with industry partners, has used advanced manufacturing and digital technologies to reconstruct an obsolete F-16 tail.

AFRL formed a partnership with private and public entities to address the challenges faced by the USAF to procure aircraft components needing repair or replacement.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Known as the Maturation of Advanced Manufacturing for Low Cost Sustainment (MAMLS) programme, the partnership focuses on using advanced technologies to sustain ageing aircraft.

MAMLS seeks to accelerate advanced manufacturing and digital technologies to improve the efficiency of the US Department of Defence (DoD) sustainment operations.

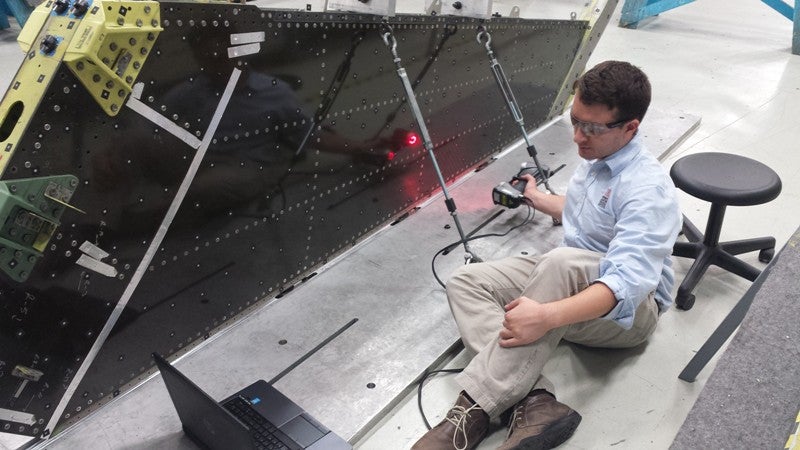

The team used a digital model to reassemble an F-16 tail that had been shot full of holes and then disassembled. The digital model of the tail was developed using reverse engineering technologies such as Laser scanning, FaroArm and Photogrammetry.

Members of the team included a MAMLS team from the University of Dayton Research Institute (UDRI) and Bill Macy Consulting, as well as Ogden Air Logistics Complex personnel at Hill Air Force Base, Utah.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe team used advanced technologies to reconstruct the tail as traditional methodologies lacked the necessary tooling and technical data.

UDRI research engineer Solomon Duning said: “The problem was that flight-critical features of the F-16 tail could not be manufactured within the technical specifications without an accurate reference.

“Reassembly with traditional methodologies would have been near-impossible; however, advanced digital methods provide new approaches to critical tasks such as these.”

The team then used the digital model to create optimised lug drilling and milling locations to configure the tail for final reassembly.

This approach allowed the researchers to reclaim an Air Force asset that would cost an estimated $600,000-$1m, based on existing rates.

Macy Consulting president Bill Macy said: “The project was able to demonstrate how digital data can be utilised to minimise the need for complex tooling and provide new repair options. As a result, lead times, costs and quality can all be effectively managed to provide enhanced repair solutions that support fleet readiness.”

Macy Consulting was hired to help complete the drilling and milling process to finish the work and return the F-16 tail to Air Force inventory.

The effort is a successful demonstration of the capability to provide repair solutions to ensure the safety of aircraft.