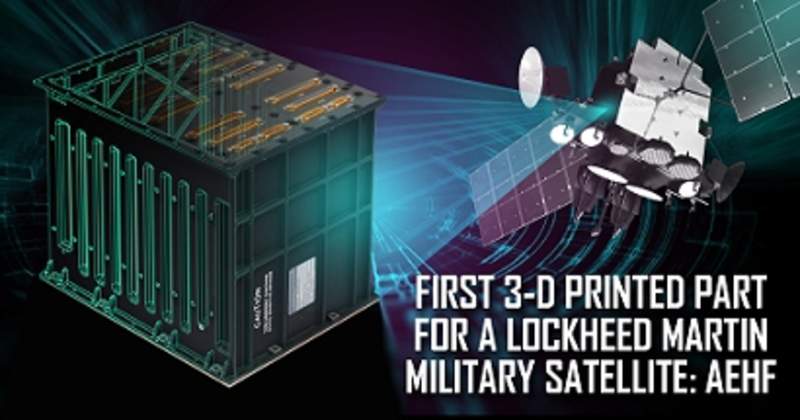

Lockheed Martin is using 3D printed parts for production of the sixth advanced extremely high-frequency (AEHF-6) satellite for the US Air Force (USAF).

A remote interface unit, which is an aluminium electronic enclosure designed to hold avionic circuits, will be the first 3D printed part certified for use on the military satellite, Lockheed stated.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The transition to 3D printed parts will reduce manufacturing lead time for a component on-board the AEHF-6 satellite by more than four months.

Lockheed Martin Space Systems protected communications vice-president Iris Bombelyn said: "3D printing provides the ability to rapidly implement innovation by controlling production from design through implementation with one digital model.

"By providing affordable, innovative solutions for our customers with a reduced timeline, we are able to adjust to the rapidly changing environment of military space."

Lockheed employed Laser Powder Bed Fusion additive manufacturing method for production of the qualified part on-board AEHF-6.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe process involves melting of a laser and fusing aluminium metal powder layer-by-layer to build a part based on a digital design.

The 3D printed electronic enclosure will serve as a model for use on other programmes that are designed using the A2100 satellite bus, Lockheed stated.

AEHF is a global military satellite communications system that is designed to provide protected, assured communication for strategic commanders and tactical personnel.

Lockheed Martin will deliver the fourth AEHF vehicle in 2017, with plans to launch AEHF-5 and AEHF-6 in 2018 and 2019 respectively.

Currently, the company uses 3D printing for design prototyping, tooling and production of affordable components.

Image: The transition to 3D printed part will reduce manufacturing lead time for a component on-board the USAF's satellite. Photo: courtesy of Lockheed Martin Corporation.