Swiss company RUAG Aerostructures has received the final approval for the airworthiness test for the first payload suspension (pylon) for Saab Gripen E/F aircraft.

This follows six years of development and industrialisation along with the production of many prototypes.

With this development, RUAG will commence serial production for more than 500 pylons, which will be installed on aircraft for the Swedish and Brazilian Air Force.

In 2015, RUAG received an Sfr80m ($77.6m) contract from Saab to supply the series production of payload mountings for the Gripen E/F fighter aircraft.

RUAG Aerostructures executive vice-president Dirk Prehn said: “With the successful acceptance of the first serially manufactured pylon, we have reached an important milestone.

“It also marked a long and successful partnership between two leading companies in the aerospace sector.”

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataPayload suspensions are designed to carry extra fuel tanks, reconnaissance systems or guided missiles.

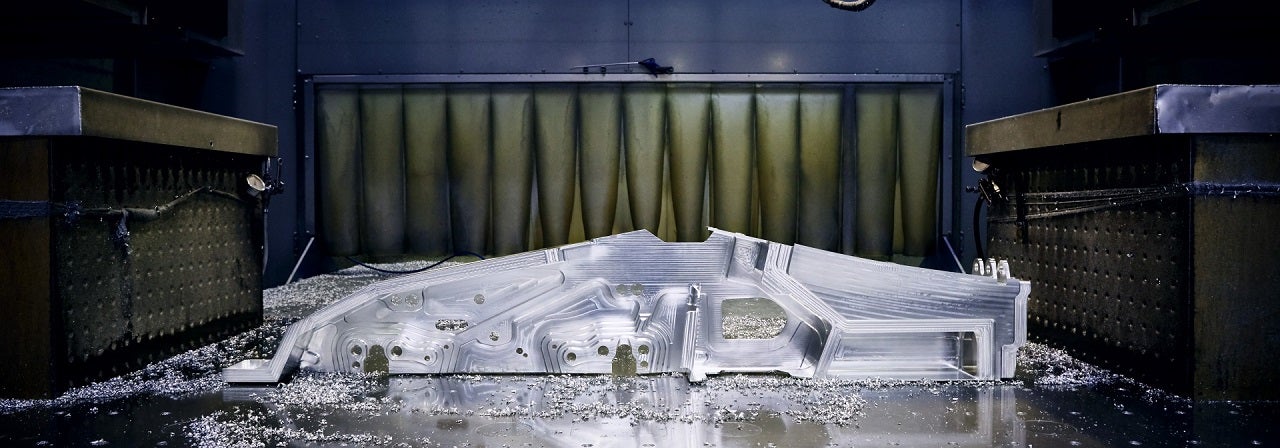

They are complex technical elements that contain electronic and mechanical systems and need to adhere to the highest aerodynamics and load capacity requirements.

Gripen E/F can be connected to up to ten racks, which includes eight that will be manufactured by RUAG.

Production of a majority of individual parts for four pylon types will be carried out at Emmen in Switzerland, which includes surface treatment and crack testing.

The units will be put through final assembly and functional testing, following which the assemblies will be handed over to the customer in Sweden.

Saab will manufacture Pylon 1 that is fitted at the end of each of the aircraft’s wings.

Saab Business Area Aeronautics Airframe Development head Hans Häggrot added: “Over the last six years we have worked very successfully with RUAG Aerostructures on the development and manufacture of the pylons.

“The payload pylons on Gripen E/F are a key component of the new aircraft’s broad operational capability.”