- Saab and Divergent Technologies use software, robotics and additive manufacturing to build an aircraft fuselage, ditching traditional tooling practices

- The platform, whose purpose is yet to be determined, is scheduled to fly sometime next year

- Saab anticipate building more than 1,000 aircraft fuselages per year in the future

- These new digital engineering methods are beginning to scale up under Divergent across the continental United States and later Europe

Saab has announced its construction of an aircraft fuselage using digital manufacturing techniques for the first time with the help of the California-based Divergent Technologies.

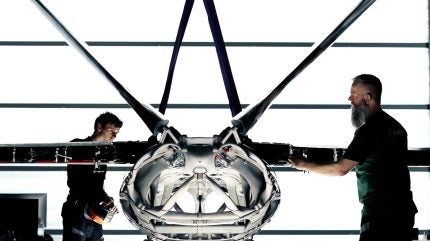

In a press briefing on 9 December, business executives from both companies revealed that the frame was produced using a combination of software, robotic assembly and laser powder fusion additive manufacturing to produce several parts that later fit together to form a single, interlocking fuselage.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

According to Axel Bååthe, head of Saab’s internal startup, The Rainforest, set up to ‘defy conventional approaches’ and drive innovation, the uncrewed autonomous aircraft is scheduled to fly sometime in 2026.

It is five metres in length, one metre wide, and 60cm high. It will have a payload capacity of roughly 200 kilogrammes.

While the Saab team have not yet pinned down a role for the platform that will take shape next year – combat, ISR, multi mission – the company claim that this new development process is a “world-first” endevaour.

What has changed?

Until now, industrial practices have been limited by simpler Euclidean geometry which made the the shape of a platform limited by what can be stamped, molded, or bent.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataIn a shift away from this practice, the transatlantic team is pursuing what is called ‘software-defined’ manufacturing, named after the central focus on software, which can make any design changes by updating a file and hitting print.

Divergent’s printer capacity is around 700 x 700 x 835 millimetres in terms of the volume that can be leveraged for a single individual part. However, Divergent’s Chief Programs and Operations Officer Cooper Keller assured: “We can extend the benefits of… additive manufacturing into structures that are far larger than that.”

Still, this newfound flexibility of the software-defined approach allows for considerable changes to be made to a design to meet multiple mission sets in the battlespace. Saab identified this one-system-many-missions requirement, particularly when it comes to military uncrewed systems (UxS).

In contrast, current manufacturing techniques mean it would cost millions of dollars in new physical jigs to alter a design.

Traditional manufacturing tends to add extra weight due to the nature of the construction process with straight lines and perfect circles. Instead, software allows for topology optimisation, meaning engineers can reduce this extra weight, leading to concepts that appear more naturalistic and organic as seen by the skeletal fuselage.

“We see compared to a traditional fuselage, a part reduction of over 99% if we count all type of attachments, fasteners, rivets,” noted Bååthe. “I think nature is very, very good at at optimisation and creating only the structure required per kilogramme of weight that needs to solve the task at hand.”

Divergent factories

Right now, there is only one Divergent factory with all of these new production systems based in Torrance, California, Keller told Airforce Technology.

However, the US company is currently “breaking ground” on a second facility with plans to build five of these digital manufacturing factories across the US over the next two years.

When asked about introducing the concept to Europe, Keller confirmed that the first factory will come to the European Union by 2028, ‘but it could happen sooner’ he suggested.

“The factories are extremely deployable,” Keller continued. “The equipment that we have built is is intended to be launched at scale and at rate. So we’ve built the printers such that they can be deployed rapidly and build the systems around them such that they can be deployed rapidly as well.”

Editor’s note: This article was amened on 11 December for clarity.