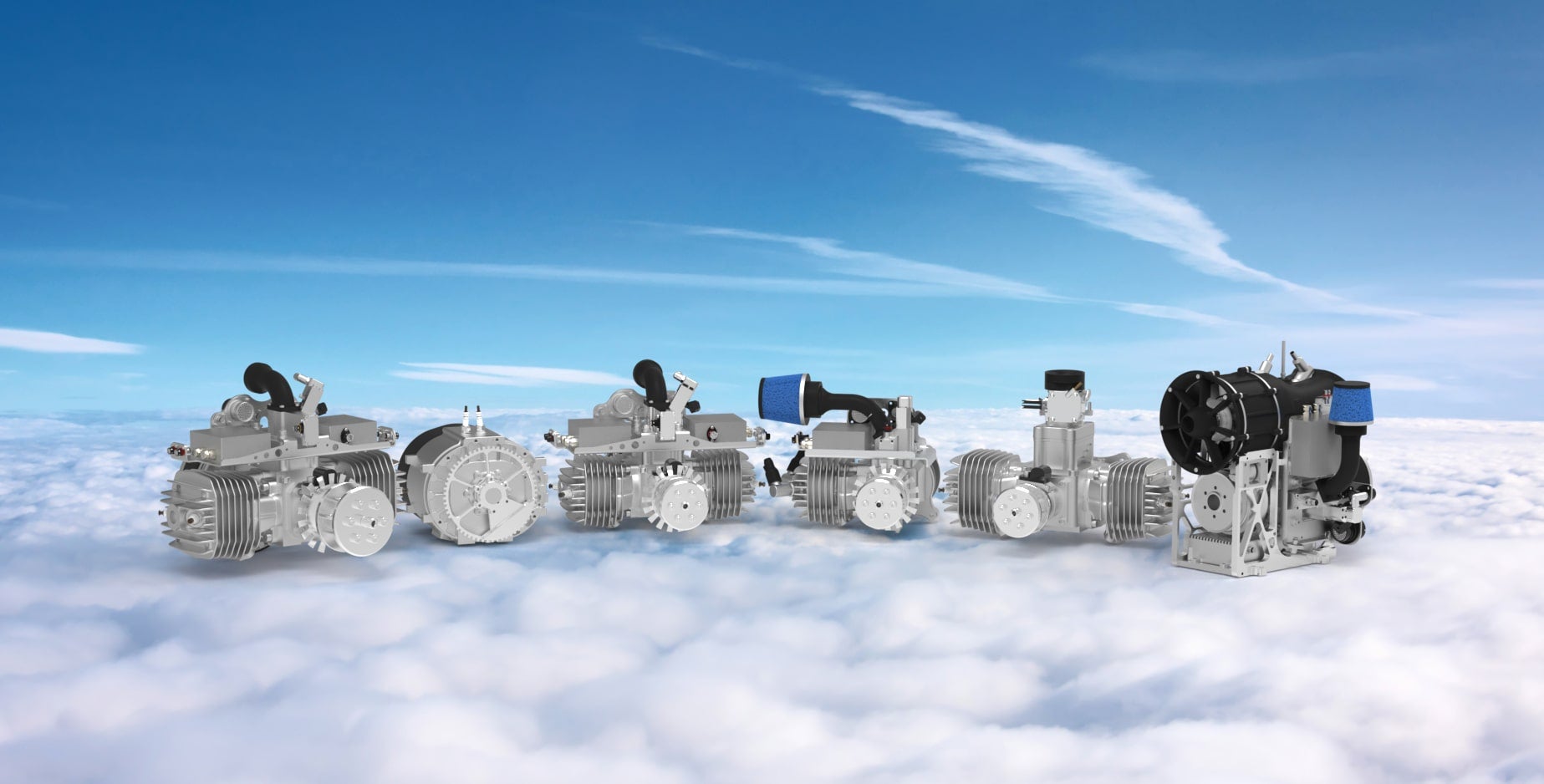

Sky Power International provides high-performance professional propulsion systems for airforce applications.

Our mission is to continue pushing the envelope with new developments towards performance, capability, reliability and value for money.

We own the newest generation of gas and heavy fuel (HF) engines for the Unmanned Aerial Systems (UAS) industry. Production and research and development of gas and heavy fuel engines are based in Germany. In addition we are offering engine designs and adaptations for existing standard engines, upon customer request.

Project management solutions for the airforce industry

Sky Power are one of the leading providers of reliable and professional products and services in our industry sectors and we continue to innovate and meet the industry’s ever-growing demand for performance, reliability and system capability.

We have customers at various stages of product development, enabling interaction with us to align with customer expectations. Some customers already know exactly what kind of propulsion performance is required. Either way, both sides must work together to specify the next steps of the project, whether a single engine or complex propulsion development.

Sky Power is flexible, agile and proactive to each customer project conditions, allowing for complete understanding and customer co-operation.

Program development and system integration services

If the objectives and expectations of our customers are not yet clearly defined, Sky Power’s consultation service is the next logical step. This may include program development as well as system integration services. The aim of the project consulting is to support the customer with technical knowledge, experience, and Sky Power’s professional opinion, to determine the project and the level of support to the customer.

Sky Power undertakes the complete project management lifecycle, from initial conceptual TRL stage through to serial production. Technical parameters, schedules and budgets must be clearly defined in advance to allow for Sky Power’s agile management of the complete UAS/project development. The earlier the cooperation starts means the more comprehensive service received from Sky Power.

Project management services

Sky Power are among the first choice globally for reliable and professional products and services in our industry sectors and we continue to innovate and meet the industry’s ever-growing demand for performance, reliability and system capability.

Many customers are at various stages of product development, enabling interaction with us to align with customer expectations. Some customers already know exactly what kind of propulsion performance is required. Either way, both sides must work together to specify the next steps of the project, whether a single engine or complex propulsion development. Sky Power is flexible, agile and proactive to each customer project conditions, allowing for complete understanding and customer co-operation.

If the objectives and expectations of our customers are not yet clearly defined, Sky Power’s consultation service is the next logical step. This may include program development as well as system integration services. The aim of the project consulting is to support the customer with technical knowledge, experience, and Sky Power’s professional opinion, to determine the project and the level of support to the customer.

Sky Power undertakes the complete project management lifecycle, from initial conceptual TRL stage through to serial production. Technical parameters, schedules and budgets must be clearly defined in advance to allow for Sky Power’s agile management of the complete UAS/project development. The earlier the cooperation starts means the more comprehensive service received from Sky Power.

Engineering services for UAS solutions

Sky Power’s engineering service offers customers a comprehensive service catalogue pertaining to the development of individual propulsion concepts, optimisation of existing propulsion structures as well as to the integration of propulsion units into UAS chassis.

In this connection, customers can rely on the over 35 years of experience that the experts at Sky Power GmbH have acquired during the development of engines and their ancillary systems.

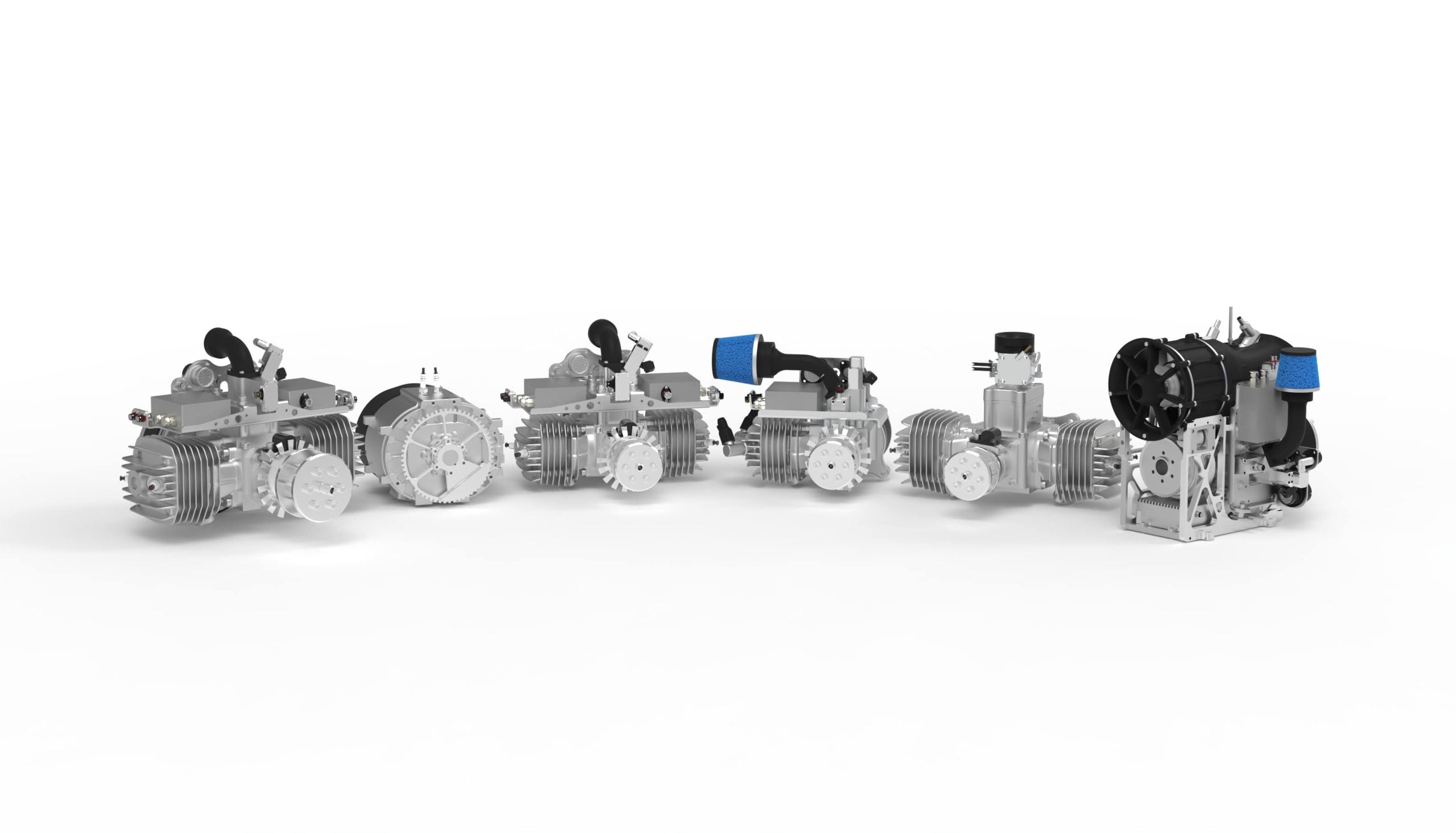

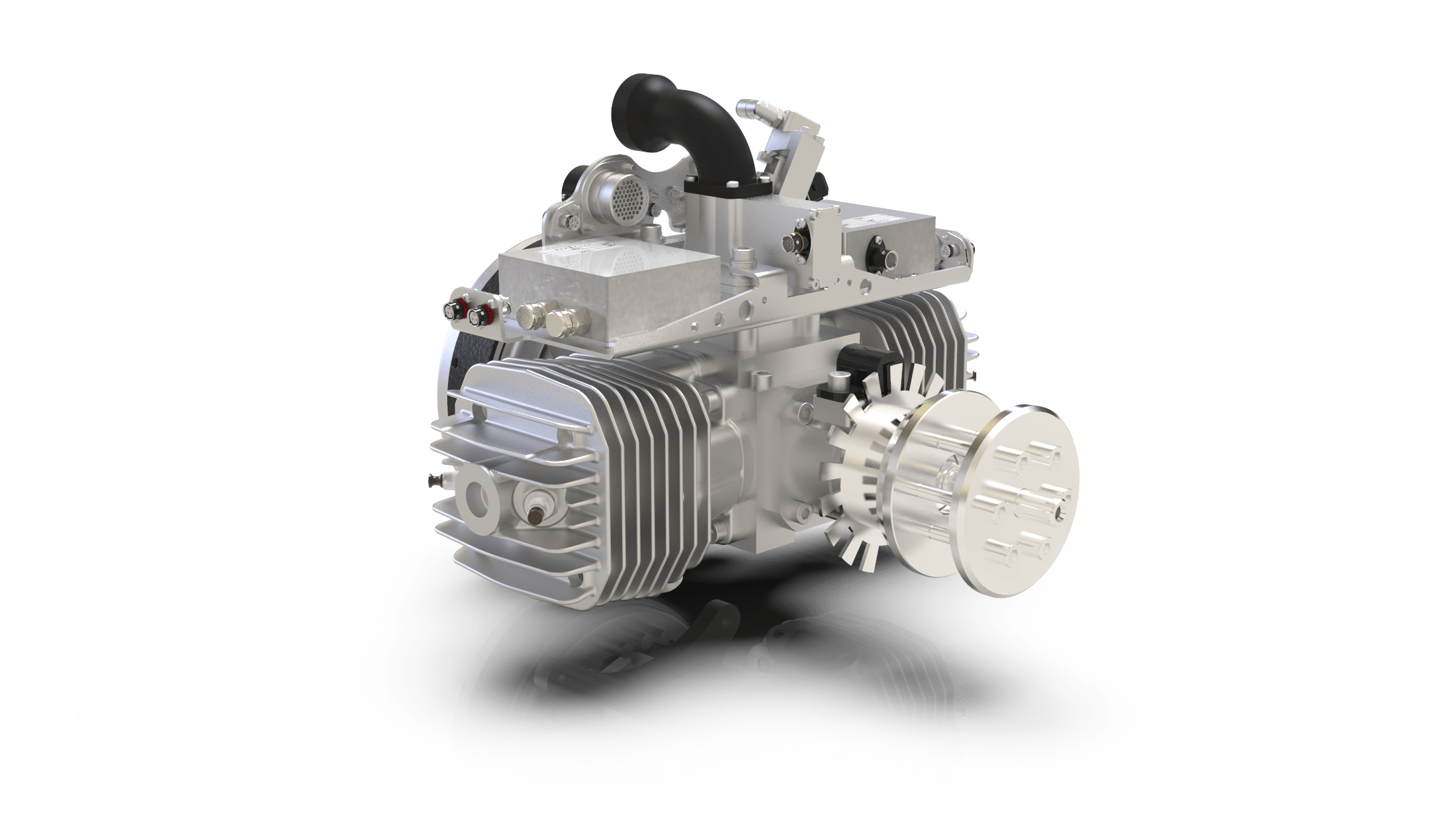

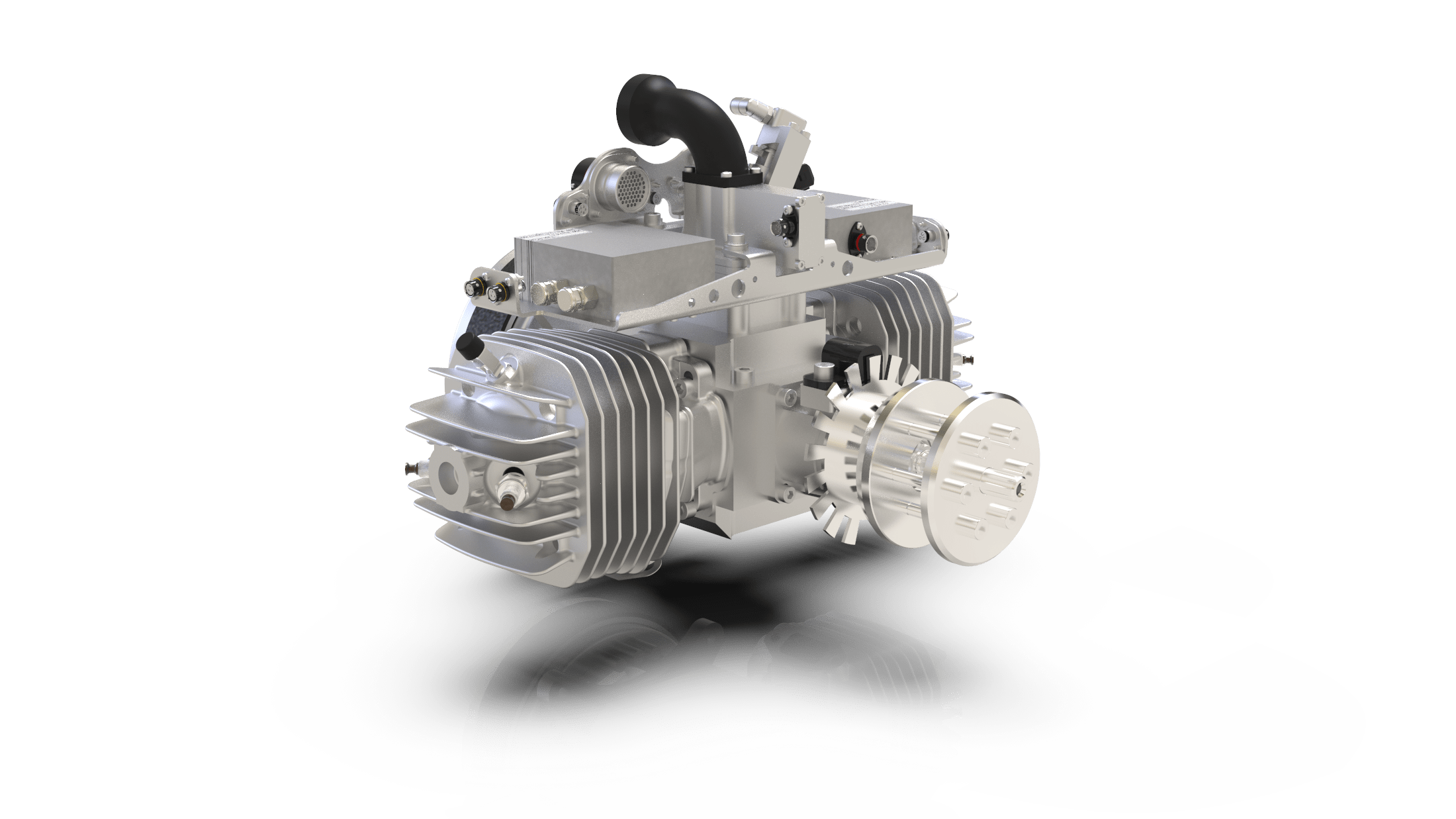

Gas and HF-engines

All Sky Power engines can be provided with either carburetor or alternatively with electronic fuel injection system. In addition beginning at 55 ccm cylinder displacement will be delivered as a twin-spark (TS) version. Both ignitions work independently of one another here.

Due to the fact that existing engines in the market did not fulfil the high standard of Sky Power International, the management decided to start their own project for a heavy fuel solution in early days. After the first prototypes had been produced, the engines were tested under various severe conditions.

At the Sky Power-test-facility, the engines had to run without difficulties. The combination of these modifications and the new development constituted the breakthrough in heavy fuel technology. The engines proved their outstanding reliability during the extensive test runs.

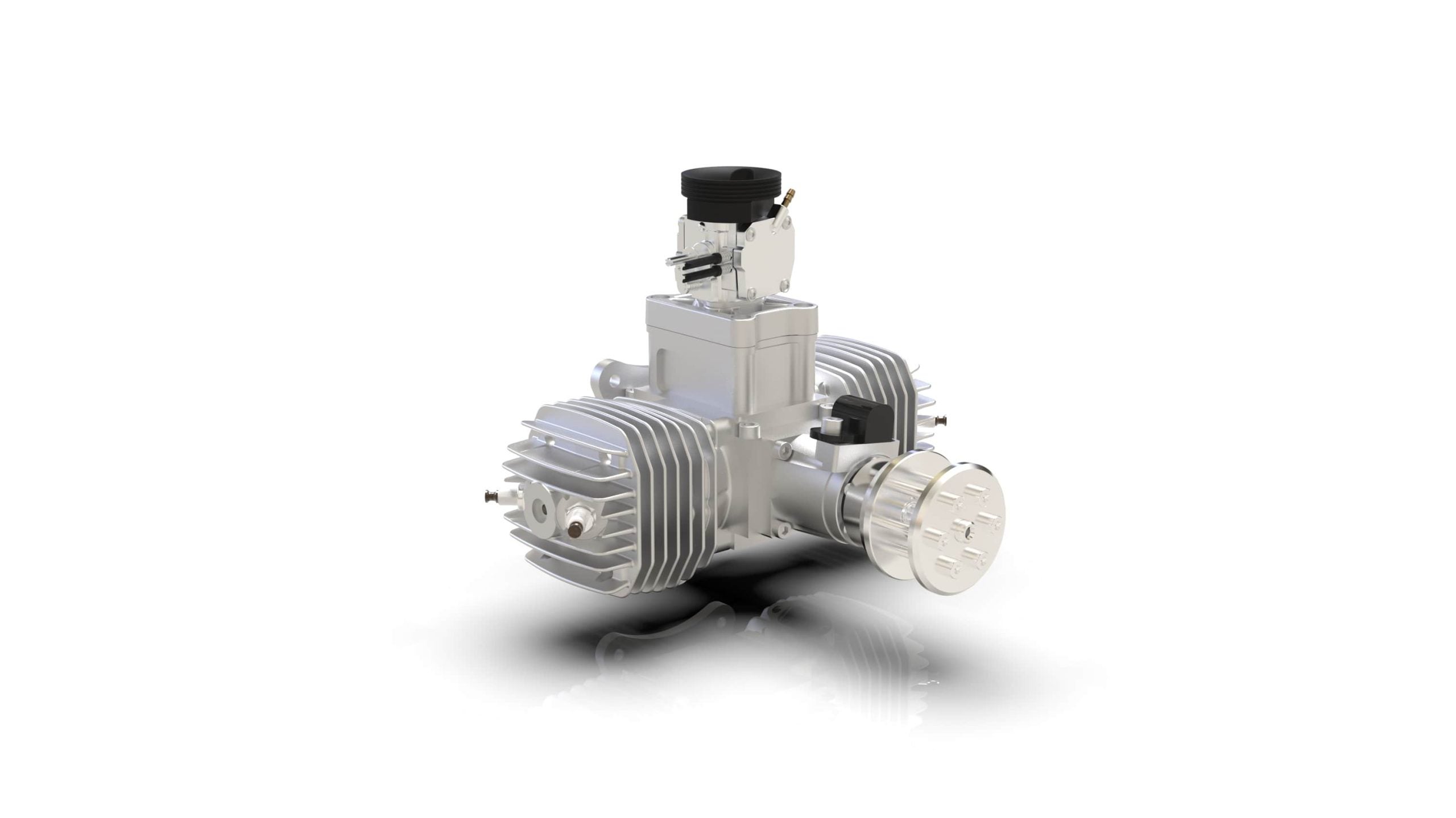

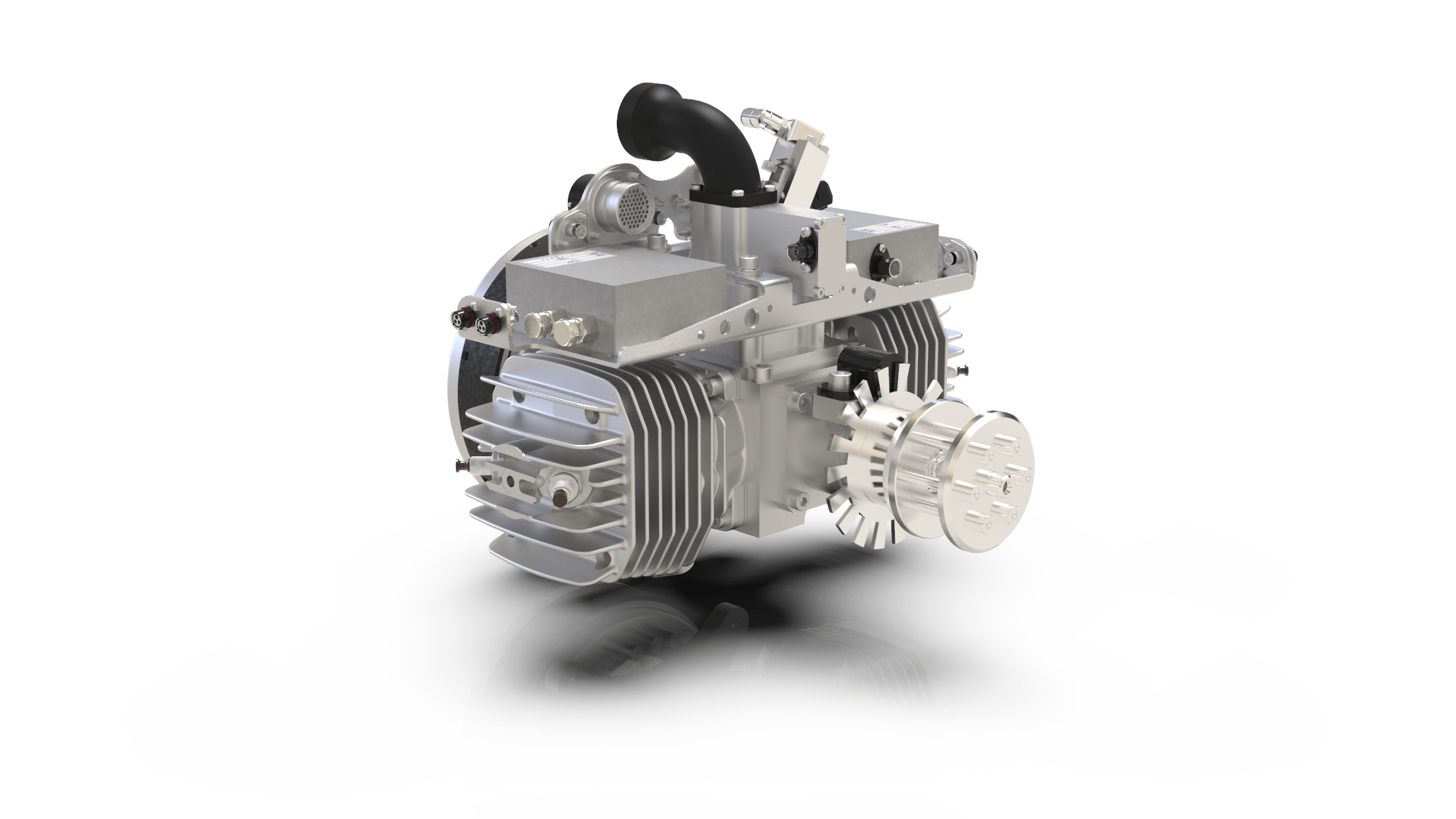

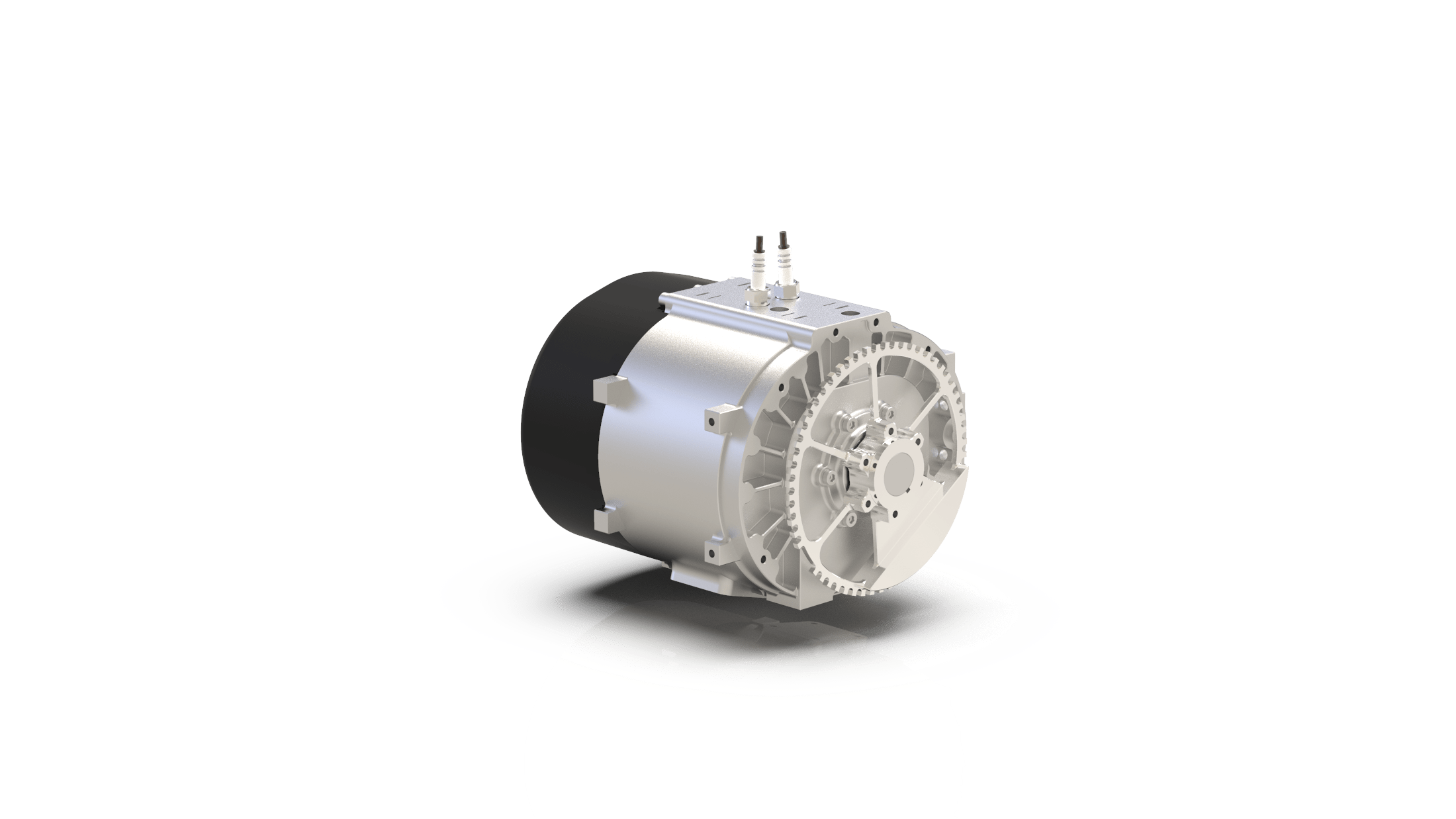

Hybrid engines for UAVs

With hybrid engines, Sky Power wants to address users of solely electric propulsion technologies who are looking for an efficient generator solution not only for unmanned flight systems but also for other applications. For UAVs, the benefits of such a generator solution are obvious. The combustion engine can extend the range or flight time as well as ensure the transport of heavy loads.

Those engines are equipped with a fuel injection system and a brushless DC motor for power generation. Furthermore, the lightweight starter generator control SGC 352, presented just recently, has been integrated. As well as the HKZ215 ignition system, which achieves considerably higher ignition performance. Thereby the overall performance of the engine increases and the exhaust emission levels are improved.

An integrated cooling system for the engine and the generator was developed to cool the entire engine unit. The engine itself sits in a sturdy aluminum frame, in which it has been installed lying on its side. The injection, control and temperature control as well as the air supply are located on the side of the engine.

The generator is mounted on the rear output shaft. The rear output shaft and the position of the fuel injection on the side make this engine one of the most compact 1-cylinder engines on the market. Above the engine and generator is the cooling system, which supplies fresh air and removes warm air.

Test bench

Testings for Sky Power and third-party engines on in-house test benches can be realized. Different test programs can be executed:

- General performance measurement of combustion engines

- Thrust and power measurement

- Exhaust analysis

- Engine indexing

- Endurance testing

- Blower, water, and oil-pump analysis

- Cylinder-head measurement

- Load-change calculation

- EMC measurements

- Climate and temperature tests