Visit our Covid-19 microsite for the latest coronavirus news, analysis and updates

Follow the latest updates of the outbreak on our timeline.

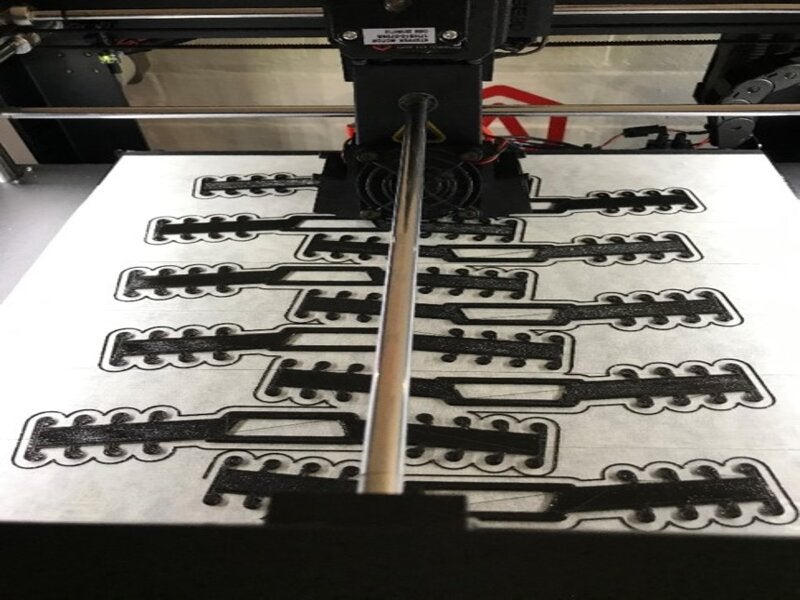

The Royal Air Force (RAF) Odiham’s Chinook Support Centre (CSC) is using a 3D printer to make supportive clips for personal protective equipment (PPE).

These clips will make wearing PPE more comfortable for the National Health Service (NHS) workers fighting the spread of coronavirus (Covid-19) pandemic.

Masks were manufactured and disturbed following the identification of a request from the 3D National Printing Society to manufacture supportive clips.

To make the masks more comfortable, the conventional elasticated straps were replaced with these supportive clips. The straps were causing pain and discomfort.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataA joint team of RAF and Boeing at RAF Odiham are supporting the UK’s fight against the virus by providing advice on engineering matters regarding Boeing Chinook aircraft.

CSC team member said: “It is great to be able to use the skills and resources that are available to me in my job and to be able to support my wife during this extremely hard time for her is really rewarding.”

Prior to the pandemic, the 3D printer at RAF Odiham was used for service modifications and special fits for the Chinook aircraft.

However, the printer currently functions around-the-clock. It produces ten clips per run in seven hours.

After a few design faults, the team has improvised to maximise the 3D printer’s output.

To date, the CSC has produced over 120 clips. The clips will be distributed through the team members’ family contacts working within the NHS.

CSC Officer Commanding Mark Goodger said: “The CSC works as a cohesive team of military and industry personnel to provide engineering solutions to the Forward Chinook Fleet; this effort has been yet another example of the teamwork and engineering innovation that the CSC strives to deliver.”